Engine

Check oil, Run engine for 30 min on mid RPM. Made sure all warks.

All looks good, little white "oil" smoke visible, smells like burned oil ;-)

Packing is not dripping, what me little bit nervous, however an hour ride next day did not heat packing box any.

Cleaned contacts on engine to control connector. Oil pressure switch contact was lost.

Interior.

temporary toilet.

Facet and sink

Head cabinet .

Built head cabinet back, panels made outstanding "countertop" for 0.5" to prevent plywood absorb water if something will be spilled on it. Glassed right wall to the hull and deck with one layer of 1708.

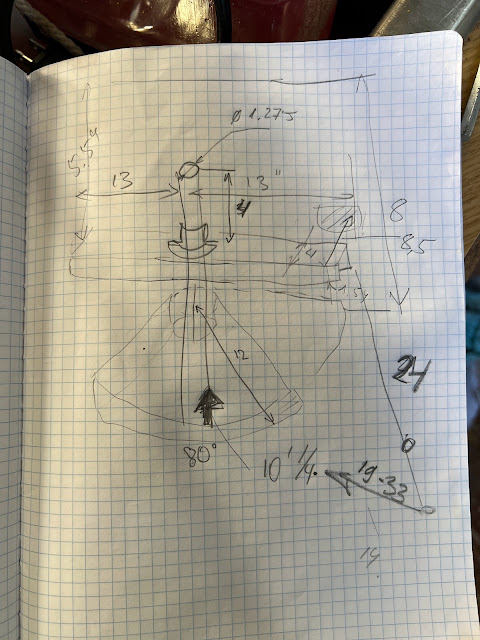

Autopilot drive project progress

A lot of calculations and chasing ideas. So, final plan is to make design close to wheel drive, but "on steroids".

Irwin 34 steering mechanism ratio and rudder stock torque calculations

Boat has wheel ~20" end to end 2.5 turns -> 900degrees

Rudder Sector turns 80 degrees

Reduction is 900:80 -> 11:1

Max reasonable force on wheel is up to 20lb, means max reasonable torque on 12" arm sector with 11:1 -> 2640 lb.in

or 300Nm

I am looking to put 300mm wheel on the rudder stock and drive it with timing belt.

Force on 300 mm wheel should be 300 N.m /0.15m = 2000N - this is starting point for belt selection.

HTD 18mm belt with fiberglass cord selected

Belt pointed to be used - 18mm -> Force 130 N/mm * 18mm -> 2340N

Belt has 17% spare capacity.

Belt transfer reduction

300mm big wheel and 37mm (24 teeth) small sprocket -> reduction 8.1:1

Motor I have on hands

SIM motor 200W , looks like big overkill, but I have two of them and I may run it at 20% power and it will work forever. (maybe not very efficient, but will see)

RPM:4300, torque 4 lb.in = 0.45 N.m

Final torque/speed calculation.

with 100:1 gearbox and 8.1:1 belt 0.45Nm*810 -> 364N/m

And final RPM 4300/810 -> 5RPM on maximum power -> Or 11sec on rotation -> or 2.5 sec end to end. I will need to restrict speed :-)

Comments

Post a Comment