Day 50, 10/1, Inverters test, Day Water tank diaster, Cockpit drains Test, Make wind instrument mount from aluminum, temporary table top in galey. 8 hours

Dock

New dock place, new ducks.

As soon as I moved to another dock and it is even more narrow than I had before, literally 10 inch wider than beam. I had to figure out what to do with dock corners to get to dock more or less safe.

Electrical

3000W Inverter.

Inverter "Dry" test to run Air conditioner. Tested with one Dual purpose battery as source. My litium batteries are still under construction. Air conditioner works well, Maximum load notified - 1200W. So far so good.

Small (400W) inverter

Checked with refrigerator - works well. Refrigerator tag says 0.8A so it is way below

Cockpit drains

Tested drains, found my older son who helped me last week did not tight clamps. inconvenience is fixed.

Wind instrument

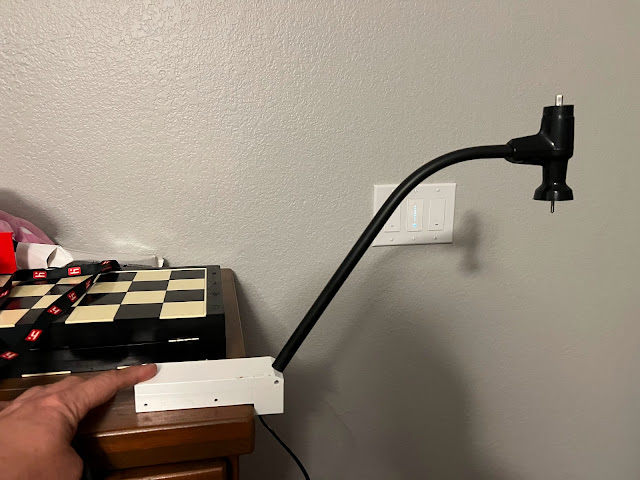

Custom mount for mast top wind instrument.

Cut it from solid aluminum 2x2x5" aluminum block. Little bit too much shavings ;)

Main cut is finished. Now need to drill holes in it.

Final product:

Interior.

As soon as took off galley countertop, i had to drop something for now to have some stable horizontal surface to work. also moved small refrigerator under stove place.

It looks sweet place for it, but due to stove has to be gambled no way to leave it there for future.

Water tank

Previously i tryed to fill tank with water and found in a wee all water appeared in the bilge. as soon as watertank is built I suspected one of hoses in leak. I decided to figure out where it is leaking. First, I had to close gate valve. I found the gate valve on tank outlet is stacked, so, took it out, unsized and cleaned it. It was not too hard.

I closed it and filled the tank...and found nice stream running from the bottom of the tank. So, I had to open it.

Several observations pushing me to spend $$$ to redo it.

Lid appeared just painted plywood. it rotted, of course.

Tank surface has a lot of pinholes in internal surface showing some brown residue there.

Nobody knows what paint is there. It is not drinking water solution at all.

Bottom corner has lateral crack on the very bottom. so it has to be re-glassed.

Conclusion. Tank has to be rebuilt using proper materials compatible with drinking water.

I went shopping for FDA approved coating material approved for drinking water tanks.

Most of products this class sold in barrels quantities. However I found three products may be used and sold in more of less realistic packages.

Tankguard DW

https://www.jotun.com/us-en/industries/products/Tankguard-DW. Sold in 40 gallon containers.

LiquaTile 1172 $278@3qt

http://www.wolverinecoatings.com/TDS/LiquaTile_1172-TDS.pdf

http://www.epoxyusa.com/ (site is sketchy but order sent next day)

Total boats recommended TotalBoat Polyester Finishing Resin but it is not certified for potable water.

Comments

Post a Comment